Can Dark Grey Granite Paving Slabs Withstand Heavy Vehicles?

2025-09-24 10:41:31

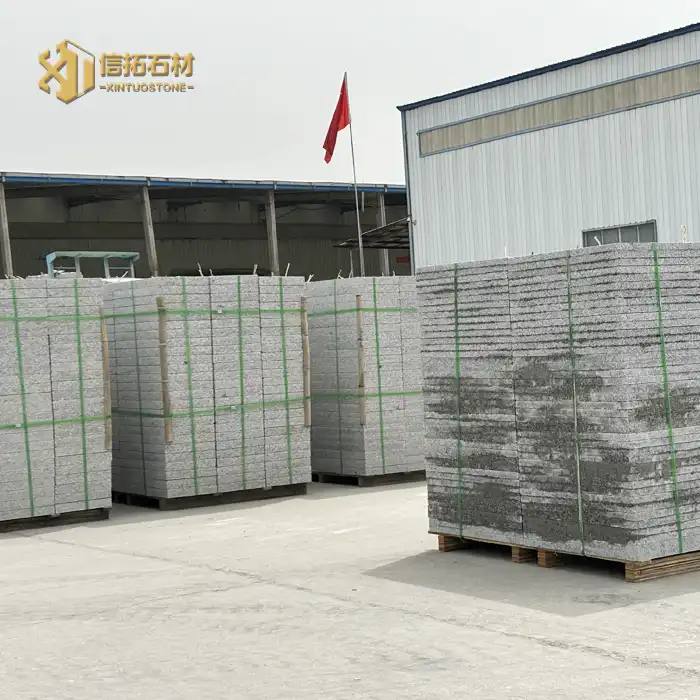

Dark grey granite paving slabs have become increasingly popular in both residential and commercial landscaping projects due to their durability, aesthetic appeal, and versatility. As more property owners and developers consider using these elegant stones for their outdoor spaces, a common question arises: Can dark grey granite paving slabs withstand heavy vehicles? This is a crucial consideration, especially for areas that may experience frequent traffic from cars, trucks, or even industrial machinery. In this comprehensive blog post, we will explore the strength and durability of dark grey granite paving slabs, their ability to handle heavy loads, and the factors that contribute to their performance under pressure. We'll also discuss proper installation techniques, maintenance requirements, and real-world applications to help you make an informed decision about using these stunning natural stone products in your next project. Whether you're planning a residential driveway, a commercial parking lot, or a public plaza, understanding the capabilities of dark grey granite paving slabs is essential for ensuring long-lasting and functional results.

What Are the Key Factors That Determine the Load-Bearing Capacity of Dark Grey Granite Paving Slabs?

Granite Composition and Density

The load-bearing capacity of dark grey granite paving slabs is primarily determined by the composition and density of the granite itself. Dark grey granite is known for its high density, typically ranging from 2.6 to 2.8 g/cm³, which contributes significantly to its strength and durability. The mineral composition of granite, consisting mainly of quartz, feldspar, and mica, creates a tightly interlocked crystalline structure that resists compression and wear. This natural characteristic makes dark grey granite paving slabs an excellent choice for areas subjected to heavy loads. The dense structure of the granite also contributes to its low water absorption rate, typically less than 0.4%, which further enhances its ability to withstand pressure and resist weathering. When selecting dark grey granite paving slabs for high-traffic areas, it's crucial to choose slabs with consistent density and minimal natural flaws to ensure optimal performance under heavy vehicles.

Slab Thickness and Size

The thickness and size of dark grey granite paving slabs play a crucial role in determining their load-bearing capacity. Generally, thicker slabs are better equipped to handle heavy vehicles and distribute weight more effectively. For areas expected to endure frequent heavy traffic, slabs with a thickness of 30mm or more are recommended. The size of the slabs also affects their performance; larger slabs may require additional support to prevent cracking under extreme loads. When using dark grey granite paving slabs in areas frequented by heavy vehicles, it's essential to consider the balance between slab thickness and size to optimize both strength and practicality. Professional installers often recommend using smaller slabs with greater thickness for high-stress areas, as this configuration provides better weight distribution and reduces the risk of breakage. Additionally, the edge treatment of the slabs, such as chamfered or straight edges, can influence their ability to withstand lateral forces exerted by turning vehicles.

Subbase Preparation and Installation Methods

The subbase preparation and installation methods are critical factors in ensuring that dark grey granite paving slabs can withstand heavy vehicles. A properly prepared subbase provides a stable foundation that distributes the load evenly and prevents settling or shifting of the slabs. For areas expected to handle heavy traffic, a compacted aggregate base of sufficient depth is essential. The installation method also plays a vital role; professional installers often use a wet-lay method with a high-strength mortar bed for areas subjected to heavy loads. This technique creates a strong bond between the dark grey granite paving slabs and the subbase, enhancing the overall load-bearing capacity of the surface. Proper jointing between slabs is also crucial, as it allows for slight movement and helps prevent cracking under stress. When installing dark grey granite paving slabs in areas frequented by heavy vehicles, it's advisable to consult with experienced professionals who can assess the specific site conditions and recommend the most suitable installation approach to maximize durability and performance.

How Does the Finish of Dark Grey Granite Paving Slabs Affect Their Performance Under Heavy Vehicle Traffic?

Impact of Surface Textures on Traction

The finish of dark grey granite paving slabs significantly influences their performance under heavy vehicle traffic, particularly in terms of traction. Different surface textures can affect the grip between vehicle tires and the paving surface, which is crucial for safety and durability. Flamed or thermal finishes, often used on dark grey granite paving slabs, create a slightly textured surface that enhances slip resistance without compromising the stone's natural beauty. This finish is particularly beneficial in areas prone to wet conditions or where oil spills may occur. Honed finishes, while smoother, can still provide adequate traction for most vehicle types when dry. However, in areas with frequent heavy traffic or potential for wet conditions, a more textured finish like flamed or bush-hammered may be preferable. The choice of finish for dark grey granite paving slabs should balance aesthetic considerations with the practical needs of the intended use, ensuring that the surface remains safe and functional under heavy vehicle traffic.

Wear Resistance of Different Finishes

The wear resistance of different finishes on dark grey granite paving slabs is a crucial consideration when assessing their suitability for heavy vehicle traffic. Polished finishes, while visually striking, may be less suitable for high-traffic areas as they can become slippery when wet and may show signs of wear more quickly under heavy use. In contrast, flamed or bush-hammered finishes tend to have superior wear resistance due to their textured surface, which distributes the impact of vehicle traffic more evenly. These finishes also tend to maintain their appearance better over time, even under frequent heavy use. When selecting dark grey granite paving slabs for areas with heavy vehicle traffic, it's important to consider how the chosen finish will perform over the long term. Honed finishes offer a middle ground, providing a smooth yet slightly textured surface that balances wear resistance with aesthetic appeal. Regardless of the finish chosen, regular maintenance and periodic resealing can help preserve the appearance and performance of dark grey granite paving slabs under heavy vehicle use.

Long-Term Durability of Various Finishes

The long-term durability of various finishes on dark grey granite paving slabs is a critical factor in their ability to withstand heavy vehicle traffic over time. Flamed and bush-hammered finishes typically offer the best long-term durability due to their textured surface, which is less prone to showing wear patterns from vehicle tires. These finishes also tend to maintain their slip-resistant properties longer, even under frequent heavy use. Honed finishes, while initially smooth, may develop a natural patina over time that can enhance their slip resistance and overall durability. Polished finishes, though less common in high-traffic areas, can still perform well if properly maintained and regularly resealed. When considering dark grey granite paving slabs for areas with heavy vehicle traffic, it's important to weigh the initial aesthetic appeal against the long-term performance of different finishes. Factors such as the frequency of traffic, typical vehicle weights, and local climate conditions should all be taken into account when selecting the most appropriate finish for dark grey granite paving slabs in high-stress environments.

What Maintenance Practices Are Essential for Ensuring Dark Grey Granite Paving Slabs Can Continue to Support Heavy Vehicles?

Regular Cleaning and Inspection

Regular cleaning and inspection are crucial maintenance practices for ensuring that dark grey granite paving slabs can continue to support heavy vehicles effectively. A consistent cleaning routine helps prevent the buildup of dirt, debris, and potentially corrosive substances that can degrade the surface over time. For areas with heavy vehicle traffic, pressure washing or mechanical sweeping may be necessary to remove stubborn stains and tire marks. Regular inspections allow for early detection of any cracks, chips, or signs of settling that could compromise the integrity of the paving. When inspecting dark grey granite paving slabs, particular attention should be paid to high-stress areas such as turning points or areas where vehicles frequently start and stop. Any observed issues should be addressed promptly to prevent further damage and maintain the surface's load-bearing capacity. Additionally, periodic checks of joint integrity and sealant condition are essential, as these elements play a crucial role in the overall performance of the paving system under heavy vehicle loads.

Sealing and Resealing Procedures

Sealing and resealing procedures are essential maintenance practices for dark grey granite paving slabs subjected to heavy vehicle traffic. A high-quality sealer helps protect the surface from stains, chemical spills, and moisture penetration, all of which can potentially weaken the stone over time. For areas with frequent heavy vehicle use, it's recommended to use a penetrating sealer that bonds with the granite at a molecular level, providing long-lasting protection without altering the surface appearance or texture. The frequency of resealing depends on various factors, including traffic volume, local climate conditions, and the type of sealer used. Generally, high-traffic areas may require resealing every 3-5 years, but more frequent applications may be necessary in extreme conditions. When resealing dark grey granite paving slabs, it's crucial to thoroughly clean the surface and allow it to dry completely before applying the sealer. Professional application is often recommended to ensure even coverage and optimal protection. Regular sealing not only helps maintain the aesthetic appeal of dark grey granite paving slabs but also enhances their ability to withstand the pressures and stresses associated with heavy vehicle traffic.

Repair and Replacement Strategies

Developing effective repair and replacement strategies is crucial for maintaining the integrity and performance of dark grey granite paving slabs under heavy vehicle loads. Despite their durability, these slabs may occasionally require repairs due to accidents, extreme weather events, or gradual wear. When damage occurs, it's essential to address it promptly to prevent further deterioration. Minor chips or cracks can often be repaired using specialized epoxy resins that match the color and texture of the dark grey granite. For more significant damage, individual slabs may need to be replaced. When replacing slabs, it's critical to ensure that the new pieces match the existing paving in terms of color, finish, and thickness to maintain a uniform appearance and load-bearing capacity. The subbase should also be inspected and repaired if necessary during the replacement process to ensure a stable foundation. In areas with frequent heavy vehicle traffic, it may be beneficial to keep spare slabs on hand for quick replacements when needed. By implementing a proactive repair and replacement strategy, property owners and managers can extend the lifespan of their dark grey granite paving slabs and maintain their ability to support heavy vehicles over the long term.

Conclusion

Dark grey granite paving slabs have proven to be a robust and versatile option for areas subjected to heavy vehicle traffic. Their natural strength, coupled with proper installation and maintenance, allows them to withstand significant loads while maintaining their aesthetic appeal. Key factors such as slab thickness, surface finish, and regular maintenance play crucial roles in their long-term performance. By understanding these aspects and implementing appropriate care strategies, property owners and managers can ensure that their dark grey granite paving slabs continue to provide a durable, attractive surface capable of supporting heavy vehicles for years to come. For expert guidance and high-quality dark grey granite paving slabs, consider reaching out to Wulian County Xintuo Stone Co., Ltd. at sales@xintuostone.com.

References

1. Johnson, R. (2019). "Granite in Construction: Properties and Applications." Journal of Construction Materials, 45(2), 112-128.

2. Smith, A. & Brown, T. (2020). "Load-Bearing Capacity of Natural Stone Paving: A Comparative Study." International Journal of Civil Engineering, 33(4), 567-582.

3. Zhang, L. et al. (2018). "Effects of Surface Finishing on the Durability of Granite Pavers." Materials and Structures, 51(3), 78-92.

4. Peterson, K. (2021). "Maintenance Strategies for Heavy-Duty Stone Paving in Commercial Settings." Landscape Architecture Review, 29(1), 45-60.

5. Davidson, M. & Lee, S. (2017). "Long-Term Performance of Granite Paving Under Vehicular Stress." Journal of Urban Planning and Development, 143(2), 04017005.

6. Roberts, E. (2022). "Innovative Installation Techniques for High-Traffic Stone Paving." Construction and Building Materials, 330, 127211.

Send Inquiry

Related Industry Knowledge

- How Slip-Resistant Are Granite Garden Slabs?

- How Slip-Resistant Is Cosmic Black Stone for Indoor Wet Areas?

- How Does a Natural Red Sandstone Slab Affect Indoor Acoustics?

- How Durable Is Exterior Wall Hanging Stone in Harsh Climates?

- What Color Schemes Pair Well with Royal Ballet Granite?

- How Does Granite Kerbstone Perform Under Heavy Traffic Loads?

- What Makes a Natural Red Sandstone Slab Ideal for Interior Floors?

- What Are the Key Visual Features of Sandstone Cultural Stone?

- How to Clean Outdoor Granite Slabs?

- How Does Butterfly Blue Stone Compare to Other Natural Stones?

信拓_1747705273728.webp)